Résistance de démarrage moteur rotorique

Une résistance de démarrage sobre, robuste et économique

Livrée en caisse IP23.

Les résistances de démarrage sont calculées pour chaque application, puis fabriquées dans nos ateliers en acier inoxydable.

Le résultat : des résistances de démarrage qui procurent des démarrages identiques, accompagnant fidèlement les procédés même les plus rudes | vibrations, humidité, atmosphère corrosive, chaleur, froid, poussière, etc.

Les caisses sont dimensionnées pour un nombre de démarrages et un temps de calage et protégées en cas de dépassement.

Avantages

- Alimentation initiale du moteur sous tension réduite

- Grande plage de possibilités selon priorité (couple max, courant max, etc.)

- Montée en charge sans à-coups

- Economique

- Adaptable en fonction du type de couple résistant

- sans entretien

Principe

Les moteurs à bagues sont d’excellents moteurs offrant de fortes puissances et un bon compromis entre un moteur à cage très économique mais difficilement maitrisable et des servo-moteur onéreux. Ils offrent des possibilités de réglage précis et une bonne linéarité Courant/Couple autour du courant nominal.

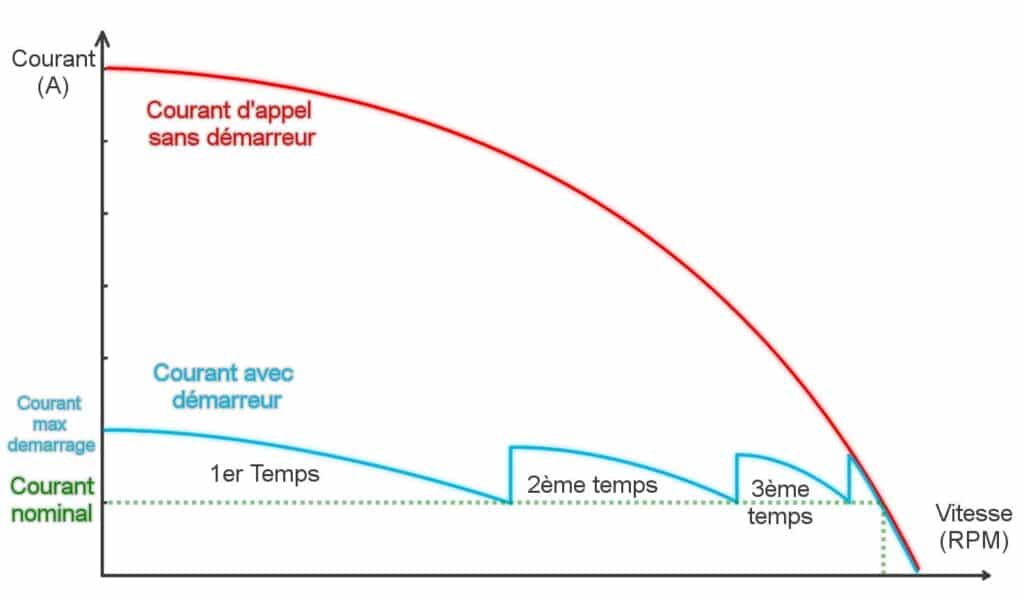

Un démarrage rotorique se fait en plusieurs temps, généralement entre 3 et 5 temps. En effet, les moteurs à bagues démarrent dans des conditions très défavorables : couple initial très faible, courant d’appel 7 fois supérieur au nominal.

Une solution économique, offrant de nombreuses possibilités et s’adaptant aux procédés, conciste à insérer des résistances dans le circuit rotorique. Les résistances sont manuvrées pendant le démarrage afin de permettre un décollage optimal du moteur. Chaque manuvre correspond a un temps. Selon les courants en jeux et le nombre de temps, il est possible soit d’ajouter des résistances en parallèle, soit de court-cirtcuiter des résistances en série, le but étant toujours de faire diminuer la résistance au cours du démarrage.

Demande de devis

Réponse sous 24h ouvrées