Automated load bank

DELTA RESISTANCES offers you its new modular system for automatic control and management of your load banks and/or generator sets.

This hardware is now integrated on our new automatic load benches, but can also be installed on any existing load bench.

It can be used to manage various functionalities, depending on requirements:

- Manual mode (touch-screen control)

- Automatic mode (Enter the desired power: the system automatically activates the sections to obtain the desired power)

- Cycle scenario management (programming of load cycles, e.g. for running-in, descaling, special cycles)

- Maintains minimum load (GE ballast)

- Measurements, test reports

- Data export.

Can be controlled locally or remotely via PC, tablet or smartphone

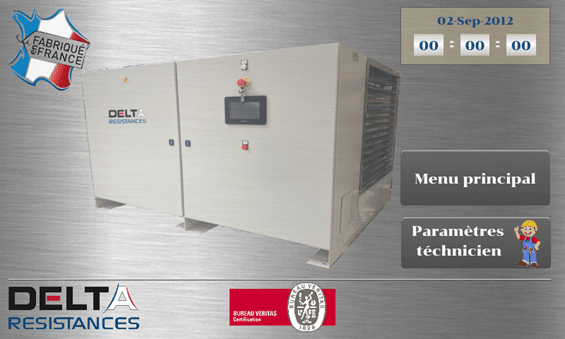

LOAD BANK MANAGEMENT SYSTEM WITH PLC AND IHM

Home page

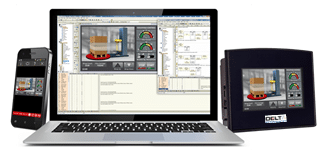

Local or (and) remote control via PC or tablet

1- Basic features :

Choice of functions - Touch screen (5", 7.5" possible)- Manual selection of load sections- Automatic control- Fault management and display in plain text

Description of basic functions :

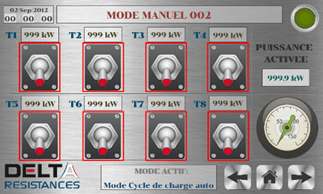

Manual mode :

- Control of individual sections

- Independent fan control

Screen view of manual controls

Automatic mode:

- Automatic section control based on a power level set on the HMI.

Once the desired power level has been selected, the system activates the load sections required to obtain this power level.

Fault and alarm management

- The system analyzes, displays and logs the type of faults that may occur on the load bank.

2-Options available: (on request)

- Automatic mode: Scenario management (honing, deslagging, etc.)

- Minimum load maintenance (ballasting)

- Measurement and data export

- Test reports

- Remote control on PC (via Ethernet or WIFI)

- Remote controls on tablets or smartphones

Optional features :

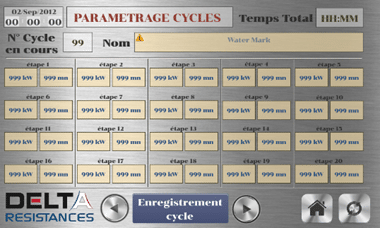

Automatic charge cycle mode:

By means of operator parameterization, the system can run charging cycles (or scenarios), such as running-in, scouring or other cycles.

Up to 15 cycles of 20 steps each can be parameterized.

Steps are defined by a power demand and a charging duration.

Load-holding mode (or generator ballasting):

This mode is used to deliver a minimum load to the generator set (GE), so that it delivers a minimum power (heel), avoiding underloading which could lead to mechanical damage (piston icing).

In this mode, the power delivered by the GE is measured by the system. If the measured power is insufficient compared to a pre-programmed minimum power, the automatic control is activated.

Loads are then deactivated as the unit ramps up.

Measurement information, value recording

This option measures the current and voltage for each phase.

Current information comes from interfaces that deliver the analog signals for each value to the PLC (3 currents, 3 voltages)

Instantaneous current, voltage and power values for each phase (three-phase network) are displayed on the HMI in a dedicated screen page selectable from the general "Menu".

Test report Data export :

This option saves data in .csv format, which can be processed in Excel and exported to a USB stick. Data can be processed on a PC with a specific application.

Test reports can be generated.

Remote controls on computer:

The commands available on the HMI can be duplicated on a remote computer (PC) by installing a free application.

The link between the PC and the load bank can be made via an Ethernet cable or a WIFI connection.

Remote control via tablet or smartphone:

The commands available on the HMI can be duplicated on a tablet or smartphone by installing a free application.

The link is made via WIFI.